Insulation Info

Closed cell does not mean waterproof, resistant perhaps, but not 100% waterproof

This also applies to spray foam insulation.

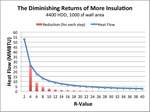

Closed-cell spray foam offers a moisture-resistant barrier that not only insulates but also adds structural strength. This type of foam can fare well in environments exposed to moisture but should not be considered waterproof. Prolonged or extreme exposure to water can eventually penetrate and affect its integrity. Keep in mind that Closed-cell spray foam has a typical R-value of R-6 per inch of thickness, you decide if it is worth double or more the cost of rigid foam board.

Spray foam insulation also tends to be a lot more permanent and can complicate repairs or upgrades down the road, whereas foam boards can simply be removed or replaced easily if the need arises.

Henry R-Tech 1 in. x 48 in. x 8 ft. expanded polystyrene (EPS) with an R3.85 for 1" Average cost per 4x8 sheet $16.00

Owens Corning FOAMULAR NGX 1 in. x 48 in. x 8 ft. extruded polystyrene (XPS) with an R5 for 1" Average cost per 4x8 sheet $32.00

RMAX Pro Select R-Matte Plus-3, 1 in. x 48 in. x 8 ft. ISO Rigid Foam Board with an R6 for 1" Average cost per 4x8 sheet $31.00

Determining the best rigid foam insulation is more complicated than looking into initial R-values alone, especially in insulation projects that are susceptible to moisture, such as under your CTC.

While XPS has an initially higher R-value of 5 per inch, it is not stable when exposed to moisture and will degrade over time. Because XPS can absorb moisture, its R-value can drop substantially over its service life. On the other hand, EPS maintains its stable R-value to provide long-lasting insulation.

Independent research has shown that over time XPS will actually absorb and retain more moisture than EPS resulting in a significant decrease in R-value. One study showed XPS retained 19% water absorption compared to 5% for EPS after being buried below grade for 15 years. As a result, the XPS samples only retained 52% of its initial R-value, EPS retained 94% of its R-value. The reason for the higher R-value retention of EPS is likely due to the comparatively higher vapor permeance property, which allows moisture absorbed in the EPS to escape more readily than XPS, most of the moisture absorbed in XPS will be retained in the XPS reducing the R-value.

If you use foam board under the trailer, EPS with the foil face (facing road) is a better way to go than XPS. Using screws through the floor to secure is not ideal, framing clips work very well if you cut the insulation to fit snugly. Spray the clips with undercoat after install.

Polyiso:

Polyiso is sensitive to temperature variations. Its R-value decreases as the temperature drops below 50°F (10°C), which means it performs worse in cold climates than in warm climates4. This can affect the overall thermal performance of the building envelope. A polyiso panel with a nominal R-value of 5.6 at 75°F can have an R-value of 2.0 at 15°F. This effect is directly related to the blowing agent used in manufacture; some brands have switched blowing agents so their polyiso panels maintain their R-values at lower temperatures so it pays to read the product sheets critically.

Polyiso is not very permeable to water vapor. It has a perm rating of less than 1 for foil-faced products and less than 5 for fiberglass-faced products. This means it can trap moisture inside the wall assembly if not properly detailed with a vapor retarder or barrier.

Polyiso is not very resistant to moisture absorption. It can absorb up to 3% of its weight in water when exposed to wet conditions. This can reduce its R-value and cause mold growth and rot.